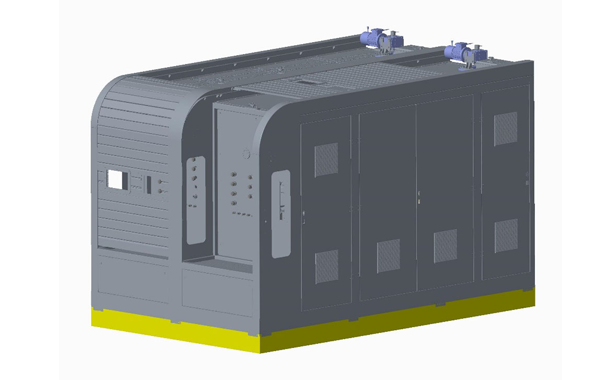

Hydraulic component reliability test bench

液压元件可靠性试验台主要适用于液压零部件制造企业,用来对零部件进行可靠性验证,以提高产品的性能和竞争力,可进行常规液压元件,如平衡阀、多路阀、电磁阀、液压锁、单向阀、蓄能器、管路接头等进行加载、冲击、额定工况、超载工况连续运转等测试,设备可靠性高,耐冲击性能好,加载能力强、能耗低,是进行液压元件可靠性试验研究的首选设备。

Hydraulic components reliability test bench is mainly suitable for hydraulic parts manufacturing enterprises, used to verify the reliability of parts, in order to improve the performance and competitiveness of products. Can carry out conventional hydraulic components, such as balance valve, multi-way valve, solenoid valve, hydraulic lock, check valve, accumulator, pipeline joint load, impact, rated condition, overload condition continuous operation and other tests, equipment reliability, good impact resistance, strong loading capacity, low energy consumption, is the first choice for hydraulic components reliability test research equipment.

| 总功率/ Total power | 15-400kW | 可定制 |

| 加载压力/ Loading pressure | 0-500bar无级加载 | 可定制 |

| 流量范围/ Flow range | 0-100L/min | 可定制 |

| 温控形式/ Temperature control form | 水冷、风冷、油冷机 | 可选配 |

| 环境油温/ Ambient oil temperature | -10~40°C | -- |

| 测试精度/ Test accuracy | B、C级精度 | -- |

| 防护门形式/ Protective door form | 电动、手动 | 选配 |

技术特点/ Technical characteristics

高效:自动化测试流程、测试元件自动装夹,极大的提高了测试效率

可靠:主要零部件均采用进口或国内一线品牌

节能:压力和流量均可比例调节,加载性能稳定,控制更加精准

安全:配备自动安全防护系统,既可以保证操作人员的人身安全又可以提升美观程度

High efficiency: Automatic test process and automatic clamping of test components greatly improve the test efficiency

Reliable: The main parts are imported or domestic first-line brands

Energy saving: pressure and flow can be proportionally adjusted, stable loading performance, more accurate control

Safety: Equipped with automatic safety protection system, can not only ensure the personal safety of operators but also improve the aesthetic degree

| 总功率/ Total power | 15-400kW | 可定制 |

| 加载压力/ Loading pressure | 0-500bar无级加载 | 可定制 |

| 流量范围/ Flow range | 0-100L/min | 可定制 |

| 温控形式/ Temperature control form | 水冷、风冷、油冷机 | 可选配 |

| 环境油温/ Ambient oil temperature | -10~40°C | -- |

| 测试精度/ Test accuracy | B、C级精度 | -- |

| 防护门形式/ Protective door form | 电动、手动 | 选配 |

组成单元/ Constituent unit

液压动力单元、油液回收单元、外供油源单元、油温控制单元、负载模拟单元、泄漏测试单元、液压油箱单元、控制和数据采集单元、试验台外形套件、各类试验工装

Hydraulic power unit, oil recovery unit, external oil supply source unit, oil temperature control unit, load simulation unit, leakage test unit, hydraulic tank unit, control and data acquisition unit, test bench contour kit, all kinds of test tools

试验标准/ Test standard

JBT 10374-2002 液压溢流阀

JBT 10364-2014液压单向阀

JBT 10374-2002 液压溢流阀

JBT 8729.2-1998 液压多路换向阀 试验方法

JB-T 9739.1-2000 汽车起重机和轮胎起重机 平衡阀

JBT 10365-2014液压电磁换向阀

试验项目/ Test item

1、平衡阀可靠性测试 Balance valve reliability test

2、多路阀可靠性测试 Multiway valve reliability test

3、电磁换向阀、手动换向阀可靠性测试 Reliability test of solenoid directional valve and manual directional valve

4、液压锁、单向阀可靠性测试 Reliability test of hydraulic lock and check valve

5、液压附件耐冲击及可靠性测试 Impact resistance and reliability testing of hydraulic accessories

秉承“高效、完善”的理念,履行给每一个客户的承诺。

Adhering to the concept of "high efficiency and perfection", we fulfill the promise to every customer.